Selective Laser Sintering //

SLS 3D Printing

- Build Complex Geometries with Fine Detail

- Produces High-Performance Isotropic Parts

- Ideal for Rapid Prototypes & Production Parts

Get a Quote

Or Any of Our 25+ Manufacturing Processes

Revolutionize Your Product Development

with Selective Laser Sintering (SLS)

Complex, High‑Performance Parts Made Simple

Are you looking for an additive technology that you can use to build parts with complex, organic geometries that are also durable? Whether you’re a designer or engineer, Selective Laser Sintering (SLS) offers you the freedom to create intricate, high-quality parts with unmatched precision.

SLS can produce parts with finer details than most other additive processes that use high-strength plastics. The composition is one of the more isotropic available from additive manufacturing. Fathom offers a wide range of machine sizes and capacity to meet all your SLS production needs.

SLS Parts in as Soon as 2 Days // Get A Quote

- How Does Selective Laser Sintering Work?

- Applications of Selective Laser Sintering

- What Does SLS Make Possible?

- What Can SLS be Paired With?

- Traditional Technologies That Can Benefit from SLS

- SLS Materials Available

- Check Out These SLS Printed Parts

- Finishing Options for SLS Parts

- Why Choose Selective Laser Sintering?

How Does Selective Laser Sintering Work?

Selective Laser Sintering uses a blade to spread a thin layer of powder over the build platform. A laser is used to sinter or fuse a 2D cross-section of the part together. The laser over-penetrates into the layer below it, also adhering the top layer to the one below it. The build platform then drops one layer and the process begins again until the part is finished.

Parts are then excavated from the build powder cake. Excess powder is removed and can be reused. The powder also acts as a support structure, eliminating the need for extra support structures that would then have to be removed in post-processing.

Applications of SLS

Concept Models // Because SLS can be used to produce complex shapes with fine detail, it’s a preferred technique for creating concept models.

Rapid Prototypes // Producing parts in SLS is fast and affordable. That makes it an excellent choice for new product innovation and rapid iteration of prototype parts. Additive manufacturing can help you avoid the expense of reworking, or even worse, completely scrapping an expensive mold.

Bridge Production // Tooling lead times for large injection molded parts tend to be quite long. SLS parts can be used to fill the gap until your tools are available.

Durable Production Parts // The isotropic strength of SLS parts gives them excellent mechanical strength in a variety of demanding applications.

Mass-Customized Parts // SLS makes it easy to simultaneously produce multiple versions of a prototype part design, or to customize part designs and quickly produce new part variations to meet fast-changing customer needs.

Industries Where SLS Parts are Used Include // Medical devices, aerospace parts, automotive components, and manufacturing

What Does SLS Make Possible?

Large Parts // Parts can be built in a wide range of sizes using Selective Laser Sintering. If a part is too large to build on a printer, Fathom can easily produce it in sections and then expertly bond it together. Need large parts? Fathom has the machines and capacity to meet your needs.

Complex Part Designs // Selective Laser Sintering can be used to produce parts with complex geometries and fine levels of surface detail that are hard to achieve with other additive manufacturing technologies. It can accommodate organic, parametric and non-parametric shapes. Except for the minimum feature size of 1 mm, there are no limitations to the complexity of shapes that can be created with Selective Laser Sintering.

Excellent Durability // Because of their excellent layer adhesion, parts produced using SLS have nearly isotropic material properties. That makes them very durable with excellent surface characteristics.

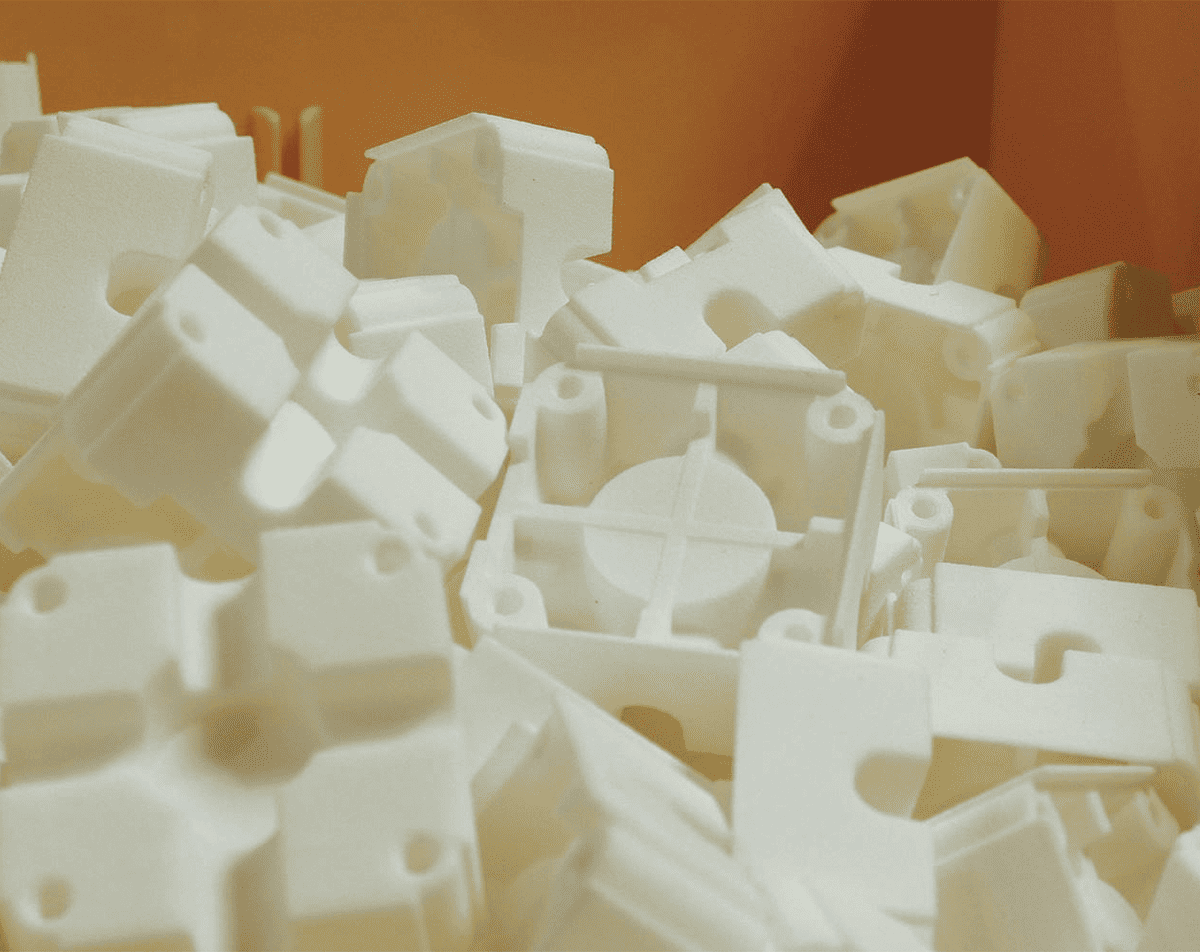

Print Multiple Parts in a Single Build // Because the powdered material serves as a support structure for the parts as they’re being fabricated, parts can be stacked in the Z direction, enabling you to get more parts out of each build.

Sustainability // No supports also means less wasted material. Most of the powder used in an SLS build can be recycled. That contributes to more affordable part costs and a greater focus on sustainability than other additive manufacturing techniques.

Affordable // SLS is cost-effective for prototyping and low production parts (up to about 1,000 pieces)

Advantages

Complex Geometries // SLS can print complex and intricate parts with fine details. That makes it well-suited for producing functional prototypes and end-use parts with unique shapes.

Produce a Large Volume of Parts Quickly // Multiple parts can be produced at the same time in a single build. The laser used during SLS has a quick scanning speed, which provides high throughput at a low cost per part.

Low Cost Per Part // Leftover powder can be reused, support structures are not required, and post-processing in SLS is less labor intensive than with other additive technologies.

Design Flexibility // SLS offers the opportunity to produce parts with complex geometries, moving parts, and pieces with interior components since this technology does not require support structures.

Superior Mechanical Properties // Because of the strong bonds between layers, parts produced using SLS tend to have excellent isotropic properties. That means they have similar tensile strength and hardness across all three axes. This makes it an excellent alternative to plastic injection molding.

Colorability // Unlike parts produced using some other 3D printing technologies, SLS parts can be dyed or colored.

Disadvantages

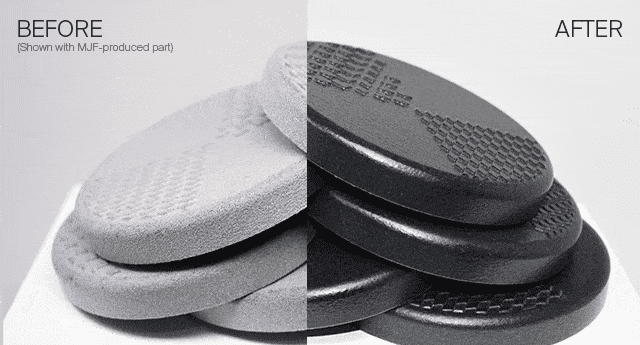

Surface Quality // Parts produced using SLS tend to have a porous surface and may need post-processing steps like sanding or coating to provide the required surface finish. One common treatment Fathom uses is vapor smoothing, which produces a smooth, waterproof surface.

Shrinkage // SLS parts tend to shrink slightly as the fused powder cools. To maintain dimensional accuracy, engineers need to plan for this when designing parts for production using SLS.

Warpage // Due to the high heat of the printing process, SLS parts can sometimes warp or deform. That can affect their accuracy and dimensional stability. Your Fathom engineering expert can help you tweak your part design to avoid this problem.

What Can SLS be Paired With?

Selective Laser Sintering isn’t just for prototyping. It can be used to produce small quantities of production parts – ideal if you’re waiting for your injection mold tooling to be completed.

Because SLS works with thermoplastics, it can be used to quickly and affordably create functional prototypes for new product designs that will later be produced using injection molding. With our cross-functional engineering expertise, we can help you tweak your part designs so they work well in both environments.

SLS can be used to build work holding fixtures to secure metal parts for CNC machining. It’s especially well-suited for larger jigs and fixtures because of the large build volumes it makes possible and its small-feature accuracy.

If tight tolerances are needed, a part can be 3D printed with the critical dimensions oversized. It can then be machined to the required tolerance.

Alternatives to SLS

For parts that require excellent impact strength, high temperature performance, water resistance, stiffness and rigidity, or if you need higher resolution or better surface finish, Stereolithography (SLA) is a viable alternative.

If you need better isotropic characteristics, then you should consider Multi-Jet Fusion (MJF).

Traditional Technologies That Can Benefit from SLS

Selective Laser Sintering (SLS) can be used to build part designs that aren’t possible using traditional manufacturing methods such as CNC machining and sheet metal fabrication.

It also enables fast, low-cost production of prototype or limited-run production parts – without the tooling required to make injection-molded parts.

SLS Materials Available

Common materials for production of SLS parts include nylon, glass-filled nylon and polyurethane.

Click on the link for a list of all the materials available for SLS printing with Fathom. Additional materials are available upon request.

Not sure what you need? Talk to a Fathom expert today!

Finishing Options for SLS Parts

Straight from the build table, SLS parts have a rough, porous finish. A variety of finishing options are available to enhance their appearance and performance, including:

Dyes // Because nylon is hydroscopic, it can be dyed in a variety of colors.

Coatings // Metal coatings can be applied to SLS parts to increase their tensile strength and to add electrical conductivity characteristics to them. Waterproofing can also be applied to protect them from wet environments.

Painting // SLS parts can be painted to improve their aesthetic appeal.

Talk to an expert at Fathom today to discuss your SLS post-processing needs.

Vapor Smoothing

Fathom offers AMT’s PostPro3D technology, a smart and automated post-processing solution for smoothing SLS printed parts. PostPro3D can achieve a high-quality surface finish that matches injection molding techniques when using 3D printing processes.

Why Choose Selective Laser Sintering?

Complex Geometries

SLS enables 3D printing of parts with complex geometries for prototype and production applications.

Affordability

It can be used to build a large volume of parts quickly with minimal post-processing required.

Build Size

It can be used to build large parts in sections, which can then be bonded together.

Part Validation

Because it uses popular thermoplastics like nylon, it can be used to validate part designs prior to injection molding toolmaking.

Why Choose Fathom’s SLS 3D Printing?

Fathom has the machines and capacity to help you meet your production needs faster – including SLS machines that can produce large parts.

Fathom has deep engineering expertise in a wide range of digital manufacturing methods, including 3D printing and injection molding. We can help you not only optimize your part designs for Selective Laser Sintering but also for higher-volume production using injection molding and other production methods.

In addition, Fathom offers domestic and overseas injection molding capacity that can help make your next project launch a success.

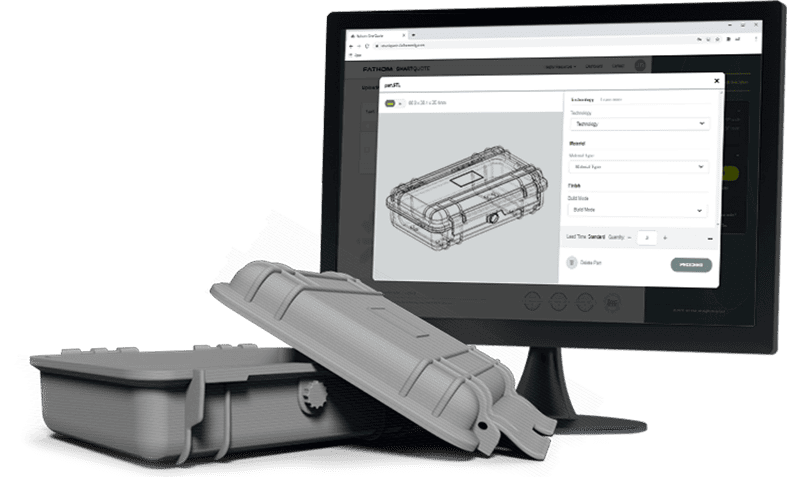

Get a quote on your SLS project today with our SmartQuote platform.