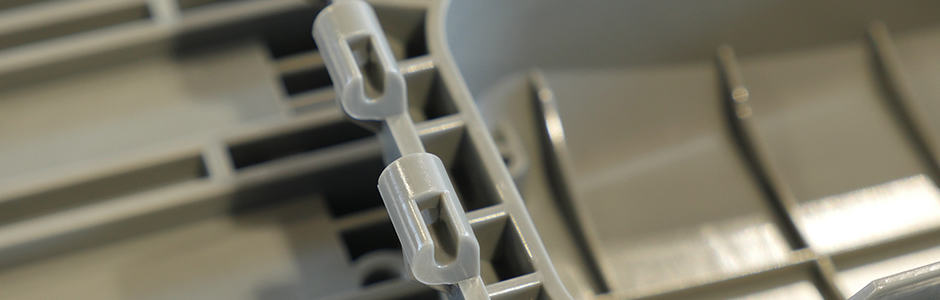

Fathom has formed the Fathom Tooling+ Team, building on more than eight decades of tooling and injection molding experience. Fathom offers a single-source global solution that supports any size company’s low- to high-volume molding needs. In-house experts working side-by-side are improving the injection mold business model—accelerating the quoting process, as well as including Design For Manufacturing (DFM) overview with every initial quote.

-

Prototype Tool In As Soon As 10 Days

-

10K Parts In 10 Days

-

Production Tool In As Soon As 3 Weeks

-

Up To 25K Parts In As Soon As 21 Days (Tools Built for 250k to 1 Million+ Shots)

-

DFM Overview Included with Every Initial Quote

ICOMold by Fathom / /

ICOMold is a now part of Fathom Manufacturing!

In addition to Fathom’s long-standing expertise in injection molding, ICOMold, one of the world’s leaders in custom injection molding parts, has joined the Fathom company.

To learn more about injection molding with ICOMold by Fathom, develop plastic injection mold cost planning for future projects or get a 30-second online quote injection mold quotes, visit ICOmold.com.